Meet New Generation Technology in Transformer Drying Ovens!

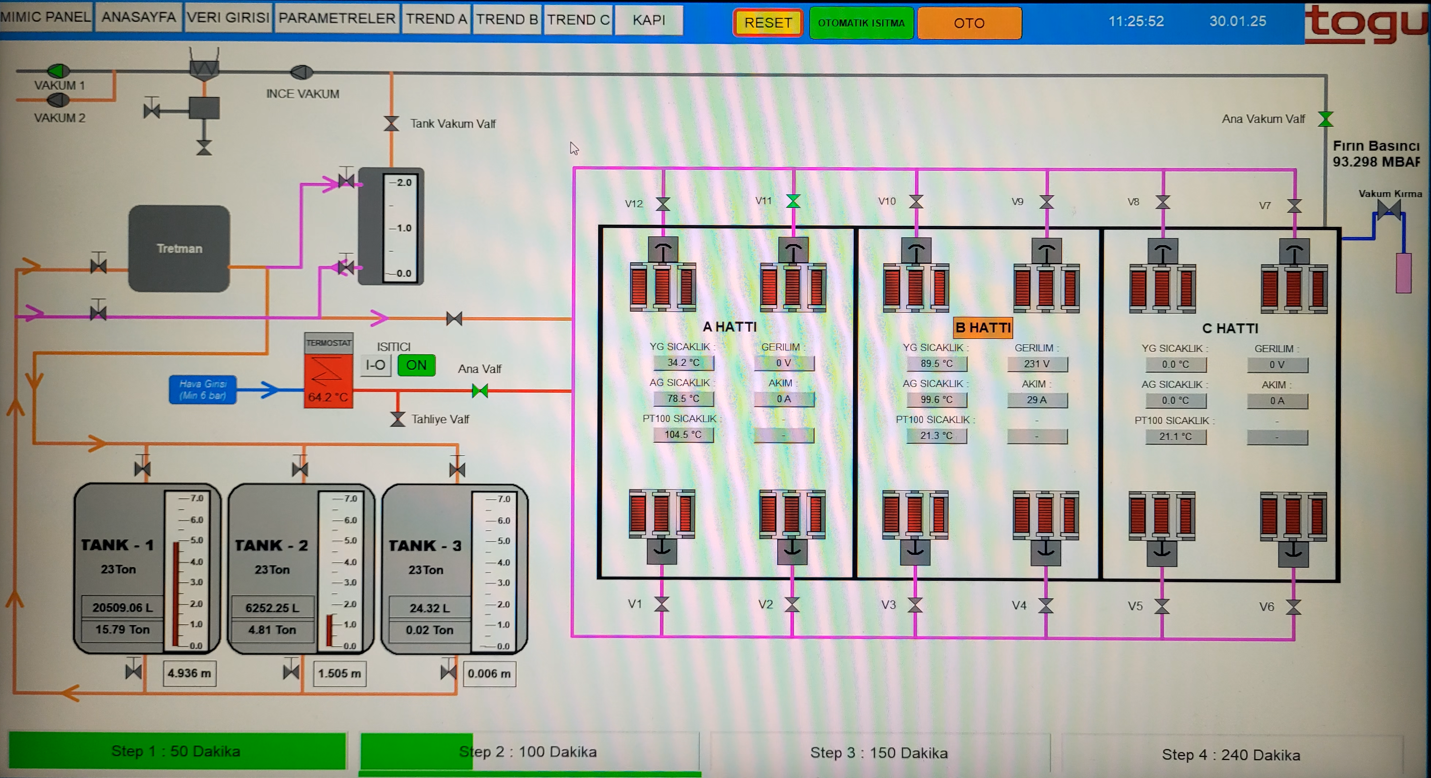

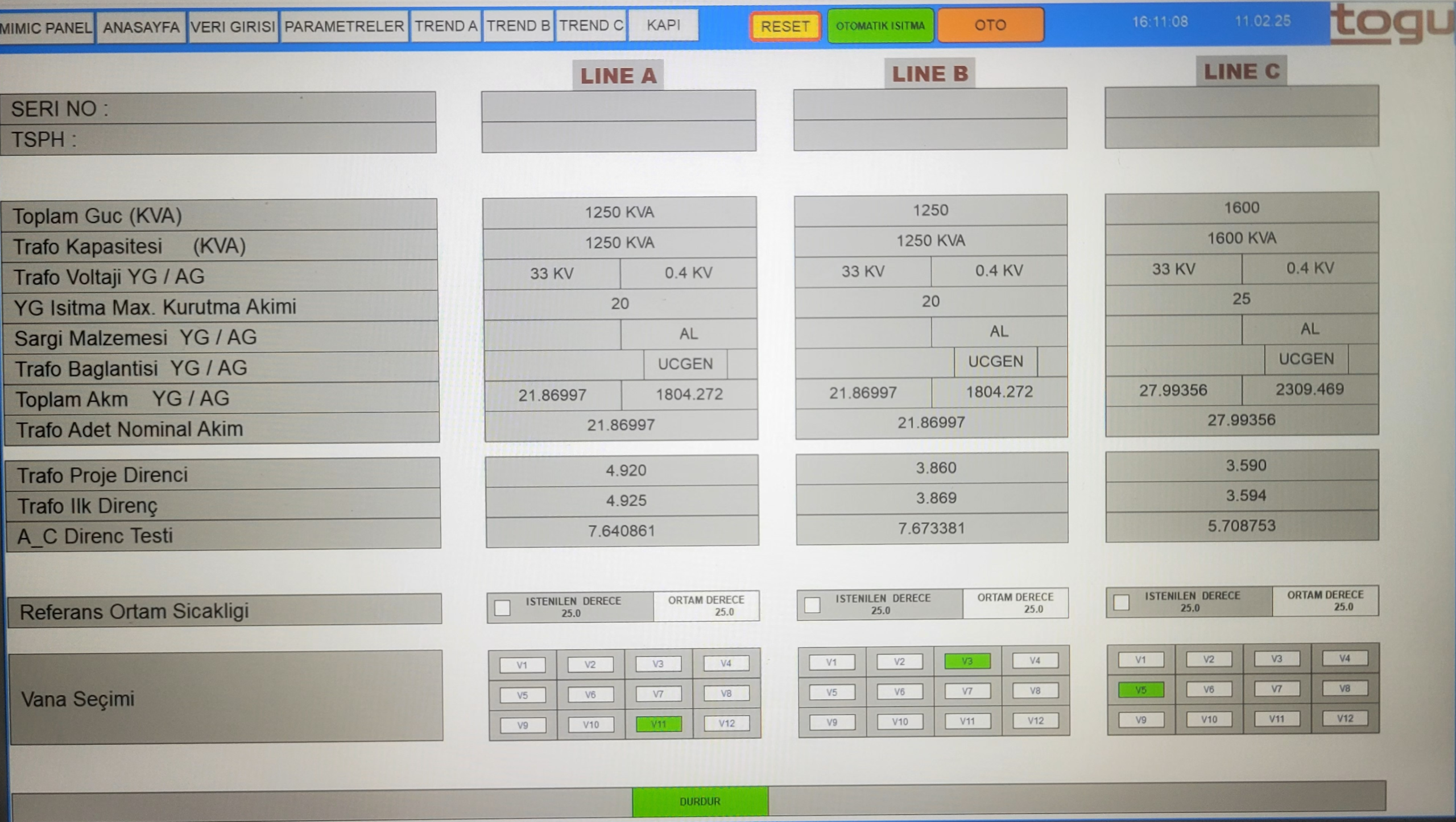

The First Step for Reliable, Efficient and Long-Lasting Transformers: Professional Drying Solutions “Direct Current Assisted Low Frequency Heating” In transformer production and maintenance processes, moisture is the biggest enemy. Our high-performance transformer drying oven ensures deep drying of windings and active parts, extending transformer life and minimizing the risk of failure.

- High Heat and Vacuum Technology: Effective moisture removal without damaging the material structure.

- Automation and Control: Precise control of temperature, vacuum and time parameters with intelligent PLC system.

- Energy Efficiency: Minimum energy consumption with insulated body structure, maximum performance with converter support.

- Different Size and Capacity Options: Customized solutions for small, medium and large transformer manufacturers.

- On-site Installation and Technical Support: Strong engineering support after sales.

- Direct Impact on Production Capacity: Direct current and alternating current are applied directly to the transformer windings through converters, thus providing a 40% gain in process times.

- Why DAD-LFH: Each manufacturer’s technology and production is different, so the temperature discrepancy between LV and HV is different. Underheating of the transformer is as much a problem as overheating is a problem.