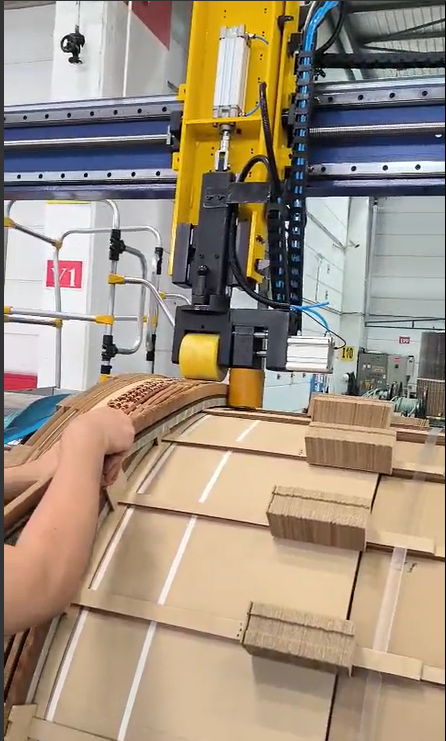

TOGU Automation supports production processes with the Transposed Compression System, developed to improve mechanical integrity and winding quality in transformer windings. This system increases both the electrical and structural reliability of the windings by ensuring that the transposed conductors are properly positioned and remain in tight form during winding.

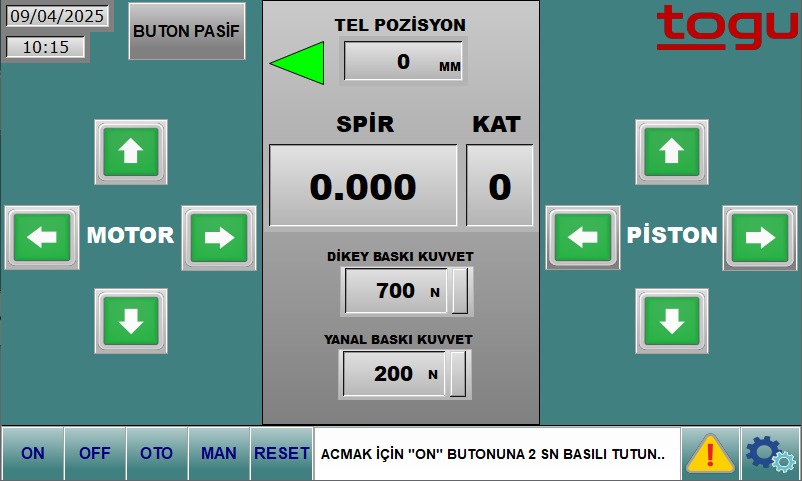

Thanks to the pneumatic system structure, the pressing force can be adjusted; it prevents the conductors from slipping, layer distortion and out of form during winding.

System Highlights

- Modular structure, compatible with different conductor sizes

- Adjustable pneumatic pressing force

- Preservation of conductor form during winding

- Performance close to automatic winding on manual machines

- Increases operator comfort and reduces the risk of errors

Adaptable and Convertible Design

Systems can be easily upgraded by integrating into existing manual winding machines. This makes winding operations more controlled, more stable and more ergonomic.